Diamond Drilling Bits

Bits Classification

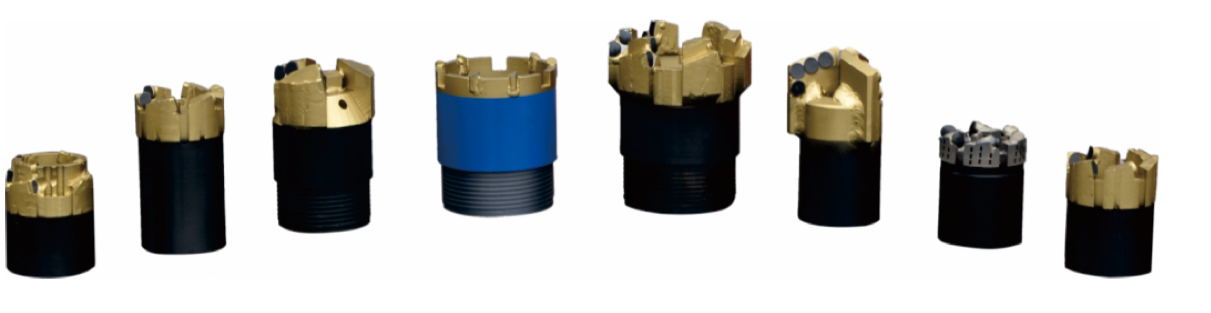

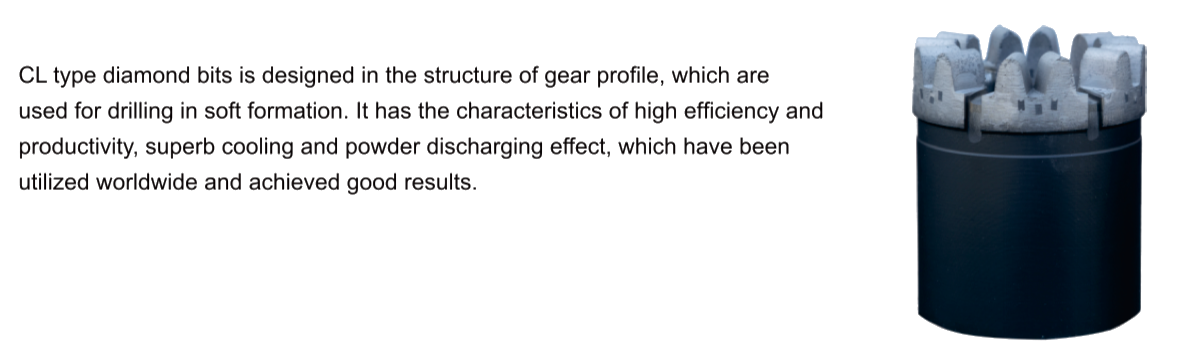

Bits can be divided into impregnated bits, surface-set diamond bits, CL diamond bits, PDC bits and TC bits.

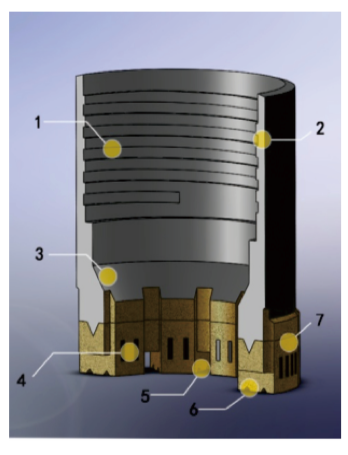

Impregnated Diamond Bits Structure

| Item | Function | |

|---|---|---|

| 1 | Thread | High precision CNC lathe processing, special thread gauge inspection |

| 2 | Bit Shank | Made of high quality alloy steel material |

| 3 | Core Lifter Seat Case | Supports core lifter case when breaking core |

| 4 | Tungsten Carbide | High wear ratio polychrystalline diameter, increase bit stability |

| 5 | Waterway | Control water flow to cool and remove rock dust |

| 6 | Profile | Ensure the new bit starts working quickly |

| 7 | Crown | Using Pre-alloyed powder, superb impregnate and control diamond, cuts rock |

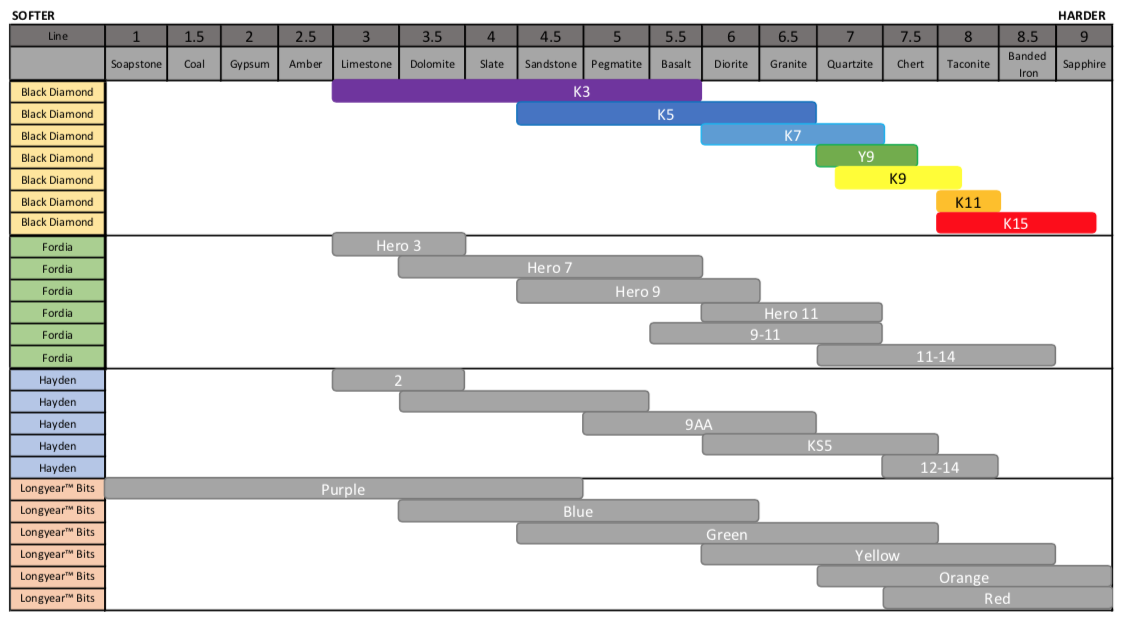

Impregnated Diamond Bits Matrix

Selection Guideline of Impregnated Diamond Bits Matrix

Impregnated Diamond Bit Coding

| Core Bit Configurations | ||||

|---|---|---|---|---|

| Type | Bit Size | Series | Matrix Height | Face Design |

| Diamond | BC | BD3 | 10 | Standard (Pie) |

| Diamond | NC-NC2-NC3 | BD5 | 12 | Turbo |

| Diamond | HC-HC3-HT | BD7 | 14 | Sand Bit (Deep Internal Waterways) |

| Diamond | PC-PC3 | BD8 | 16 | Jet Bit |

| BD9 | 18 | Wedge Water Ways | ||

| BD11 | Face Discharge | |||

| BD15 |

Guideline for Impregnated Diamond Bits Operating Parameters

Standard & Technical Parameters of Diamond Bits

Bit Range Chart - Black Diamond, Ford, Hayden, Longyear.

Core Lifters

A core lifter assembly allows the operator to clamp the core sample so the core can be broken free and retrieved to the mine surface.

Standard Core Lifters Features

BD Drill core lifters are made of high-quality alloy steel and are heat treated to increase strength, toughness and wear life.

Diamond Coated Core Lifters Features

Diamond-coated core lifters add a thin composite diamond-coating (CDC) of a hard metal alloy impregnated with synthetic micro-diamonds. The diamond coating process provides superior wear resistance. Based on field results, the diamond coated core lifter returns approximately 300% longer life as compared to a standard core lifter.

Slotted

- Ideal for use in competent ground conditions

- Increased grip area with core sample

- Also known as the "Brown Style" core lifter

Fluted

- Ideal for use in broken ground

- Increased flexibility; Ideal for use when encountering irregular core

- Also known as "Broached" core lifter

Spiral

- Ideal for use in ultra hard ground conditions

Surface-set Diamond Bits

Surface-set Diamond Bits

PDC Bits & TC Bits

PDC Bits & TC Bits